Micrometer, moreover called a micrometer screw gage, is made up of a calibrated screw. Micrometers are utilized for exact estimation of components in mechanical building and machining, beside metrological disobedient like dials, verniers, and advanced callipers. A micrometer is an instrument which is more often than not used to create precise direct estimations of measurements, like breadth, thickness, and lengths of strong bodies. A micrometer is composed of a C-shaped outline with a mobile jaw worked by an indispensably screw.

About Micrometer

A micrometer, regularly alluded to as a micrometer screw gage, may be a modern measuring instrument outlined for accomplishing exact and precise estimations of little measurements with a tall degree of unwavering quality. Broadly utilized in areas like mechanical building, fabricating, and metrology, a micrometer is fundamental for assignments requesting fastidious estimations. It is fundamentally utilized to gage the breadth, thickness, and length of strong objects, playing a vital part in quality control and guaranteeing exactness in different businesses.

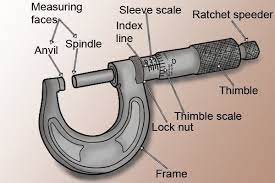

The center components of a micrometer incorporate a C-shaped outline that gives auxiliary soundness, an iron block (settled) and a shaft (mobile) which come into contact with the question being measured, a thimble joined to the shaft with calibrated markings for estimation perusing, and a sleeve that encases the thimble to defend its sensitive parts. The characterizing include of a micrometer is its calibrated screw instrument, comprising of a absolutely made strung pole interfacing the iron block and the shaft. Pivoting the thimble moves the axle, permitting for exact alterations to the estimation.

What is Micrometer?

Micrometers are undoubtedly specialized rebellious planned for exceedingly precise estimations of little direct measurements. Their accuracy and capacity to degree inside the run of 0.01mm to 0.005mm (or indeed littler depending on the particular micrometer sort) make them vital devices in applications where exactness is significant. The equipment industry, as you specified, depends intensely on micrometers to guarantee that components meet correct details, contributing to the by and large quality and usefulness of items. Whether in fabricating, investigate, or quality control, micrometers play a basic part in keeping up accuracy and consistency in different areas.

A micrometer is an instrument typically utilised to make accurate linear measurements of dimensions, like diameter, thickness, and lengths of solid bodies. A micrometer is composed of a C-shaped frame with a movable jaw functioned by an integral screw.

Parts of Micrometer

A micrometer comprises of a few basic parts that work together to empower exact and precise estimations. Here’s a breakdown of the key parts:

Frame: The outline is the external body of the micrometer, regularly planned in a C-shape to hold the inside components. It gives soundness and structure to the instrument.

Anvil: The iron block could be a settled component joined to the outline against which the question being measured is set. It gives a reference point for the estimation.

Sleeve/Barrel: The sleeve or barrel may be a round and hollow tube that houses the inside components of the micrometer. It frequently incorporates a direct scale, in some cases alluded to as a pitch scale, which makes a difference in perusing the estimation.

Screw Mechanism: The screw instrument is the heart of the micrometer. It comprises of a accurately calibrated screw that interfaces the iron block and the axle. Turning the screw by turning the thimble moves the axle, permitting for exact alteration of the estimation.

Locknut: The locknut is utilized to secure the axle in put once the protest being measured is in contact with the iron block. It prevents any accidental development that may influence the estimation.

Spindle: The shaft could be a mobile component that expands from the other side of the outline and faces the iron block. It holds the question being measured in put and moves in reaction to the turn of the thimble.

Thimble: The thimble is joined to the end of the axle and is turned to move the axle towards or absent from the iron block. It features markings, often within the frame of circular divisions, which are utilized to examined the estimation.

Ratchet: The ratchet could be a instrument ordinarily found at the conclusion of the thimble. It serves to constrain the connected weight when measuring an protest. This makes a difference avoid over-tightening, which might lead to mistakes within the estimation.

Frame Lock: A few micrometers have a outline bolt that holds the outline in a settled position, guaranteeing reliable estimations, particularly when the instrument is utilized more than once.

Zero Adjustment: Micrometers as a rule have a include for zero alteration, which permits you to calibrate the instrument to ensure exact readings.

Vernier Scale (Discretionary): In more progressed micrometers, you might discover a vernier scale nearby the most thimble scale. This extra scale gives better estimations by permitting you to introduce between the most scale divisions.

Heart of a Micrometer

The heart of a micrometer is the screw found inside the barrel.

The accuracy of the string shape of the screw decides the exactness of the estimation.

A screw’s string can be distinguished as the edges felt when touching a screw.

The string is the helical structure that changes over torque to direct constrain.

Types of Micrometers

There are two common types of micrometers:

Exterior Micrometer (or Outside Micrometer): This sort of micrometer is utilized to degree the external measurements of an question, such as its breadth or thickness. It comprises of a shaft and iron block, much just like the components I already portrayed. The protest to be measured is put between the axle and the iron block, and the thimble is pivoted to bring the axle into contact with the question. The estimation is at that point perused from the markings on the thimble and the most scale on the sleeve. Exterior micrometers are widely utilized in different businesses to guarantee exactness within the measurements of fabricated components.

Inside Micrometers : This sort of micrometer is planned to degree the inside measurements of objects, such as the breadth of a gap or the width of a groove. It ordinarily comprises of a T-shaped outline with mobile measuring jaws that can be extended or contracted inside an protest. The estimation is taken by altering the jaws interior the space to be measured and perusing the estimation from the scale on the micrometer. Interior micrometers are especially valuable when exact estimations of inside highlights are required, and they are commonly utilized in machining and building assignments.

Outside Micrometers

An outside micrometer (or pariah micrometer) is utilized to degree the external surfaces of any component. It gives precise estimations of the components and could be a exceptionally common sort of micrometers utilized in fabricating businesses.

Mechanical(Analogue) exterior Micrometer and Digital outside Micrometer The exterior micrometer is the foremost commonly utilized sort of micrometer It is utilized to degree outside measurements such as the exterior breadth of an protest.

Types of Outside Micrometers:

Standard Outside Micrometer: Typically the essential sort of exterior micrometer utilized for common estimations. It comprises of the standard components, counting a axle, iron block, thimble, and sleeve, and is reasonable for measuring level surfaces, distances across, and thicknesses.

Depth Micrometer: A profundity micrometer is utilized to degree the profundity of gaps, openings, and breaks. It incorporates a slim pole or edge that expands from the shaft, permitting it to reach into profound spaces for estimations.

Blade Micrometer: Edge micrometers have a contract, level iron block and a round and hollow shaft with a level conclusion. They are utilized to degree the thickness of lean materials like paper, movies, and foils.

Screw Thread Micrometer: This micrometer is planned particularly for measuring the pitch distance across of screw strings. It highlights specialized iron blocks and axles that adjust to the shape of strings.

V-Anvil Micrometer: V-anvil micrometers are utilized to degree the distance across of round and hollow objects. They have V-shaped iron blocks that way better hold round and hollow surfaces, guaranteeing exact estimations.

Tube Micrometer: Tube micrometers are planned to degree the thickness of tubes and channels. They frequently have more extensive iron blocks to suit the ebb and flow of the round and hollow surfaces.

Disk Micrometer: Disk micrometers are utilized to degree the thickness of little, level objects such as disks, plates, and sheets. They have level, parallel measuring surfaces.

Interchangeable Anvil Micrometer: These micrometers permit you to alter the iron blocks to oblige distinctive estimation scenarios, making them flexible for different applications.

Pistol Grip Micrometer: Gun grasp micrometers have a handle taking after a gun hold, which makes them less demanding to hold and utilize. They are commonly utilized in situations where visit estimations are required.

Digital Micrometer: Whereas not a isolated category, computerized micrometers join a computerized show to appear the estimation straightforwardly, dispensing with the require for manual perusing. They can come in different shapes, counting the standard, profundity, and other sorts said over.

Inside Micrometers

An interior micrometer, moreover known as an inner micrometer or bore micrometer, could be a specialized measuring instrument utilized to degree the inside measurements of objects such as gaps, barrels, and tubes. Not at all like exterior micrometers that degree outside measurements, interior micrometers are outlined to precisely degree the breadth, profundity, and other inside highlights of objects.

Types of Inside Micrometers:

Tubular Interior Micrometer: This can be the foremost essential sort of interior micrometer. It comprises of a T-shaped outline with a measuring pole that amplifies into the gap being measured. The measurement is studied from the scale on the thimble and the most scale on the sleeve.

Three-Point Interior Micrometer: This sort has three measuring focuses rather than two, which gives more noteworthy solidness and precision when measuring gaps that might not be impeccably circular. The three focuses guarantee that the micrometer measures the normal distance across of the gap.

Holtest (Bore Gage): Usually a more progressed sort of interior micrometer that employments a set of conversely iron blocks to degree a wide run of gap sizes. The measuring iron blocks are embedded into the gap, and a dial or advanced marker gives the estimation specifically.

Dial Marker Interior Micrometer: This sort combines an interior micrometer with a dial pointer. It offers the advantage of a visual dial show, making it simpler to examined estimations precisely.

Computerized Interior Micrometer: Comparative to the advanced exterior micrometer, this sort incorporates a advanced show that specifically appears the estimation. It disposes of the require for deciphering scale readings, improving ease of utilize and precision.

Working Principle Of Micrometer

Setting Up the Micrometer:

Open the micrometer by turning the thimble counterclockwise until the axle is withdrawn completely.

Hold the outline with one hand and turn the thimble with the other hand to move the shaft outward, guaranteeing the measuring faces are clear of obstacles.

Setting the Protest to Be Measured:

Position the question to be measured between the iron block (stationary portion) and the axle (mobile portion) of the micrometer. The protest ought to be in contact with both the iron block and the axle.

Contact and Beginning Estimation:

Tenderly pivot the thimble clockwise to move the shaft towards the question. Proceed turning until the measuring faces make light contact with the question.

Taking the Estimation:

With the measuring faces in contact, pivot the thimble assist to apply a slight weight against the protest. This guarantees a reliable and precise perusing.

As you pivot the thimble, it causes the screw instrument interior the barrel to move the axle more accurately toward the protest.

Watch the most scale on the sleeve and the circular markings on the thimble. The most scale demonstrates entire units of estimation (e.g., millimeters), whereas the thimble markings show divisions or better divisions.

To obtain the estimation, perused the esteem from the most scale where it adjusts with the thimble’s markings. The thimble markings indicate how many divisions past the most scale’s perusing you ought to consider. This is often comparable to perusing a vernier scale.

Recording the Estimation:

Note down the estimation esteem gotten from the micrometer. This esteem speaks to the exact estimation of the object’s measurement.

Withdrawing the Micrometer:

Turn the thimble counterclockwise to withdraw the axle and discharge the weight from the protest.

Closing the Micrometer:

Proceed turning the thimble counterclockwise until the shaft is completely withdrawn. This plans the micrometer for the following estimation and makes a difference secure the sensitive measuring surfaces.

Uses of Micrometer

- Micrometers are most commonly utilized in building and mechanics.

- It is utilized within the mechanical fabricating of moving parts such as cylinders where a slight botch within the measurement might lead to unfitting components. For ideal work of equipment components such as pipes and bearing, precise measurements are measured employing a micrometer.

- Advanced micrometers are presently accessible which decrease the errors that were dealt with within the manual ones. The major advantage is that these might be fitted with other equipment devices and exact estimations might be effectively taken.

FAQs

Micrometers play a crucial role in manufacturing by ensuring that components meet precise specifications, maintaining quality control, and ensuring proper fits and tolerances. They contribute to the consistency and functionality of products.

While using a micrometer requires some familiarity with its components and reading scales, with practice, they can become relatively easy to use. Digital micrometers are especially user-friendly due to their direct measurement display.