Scope Of Pursuing Textile Engineering After 12th, Textile Engineering is a department of architecture that trades with the garment, colour, and material range of businesses. It is the ability that chances with all exercises and processes which are required in the method of textile production. Textile engineering consists of the association, systems, and experimental systems which are appropriated for the construction and producing the textile substances and every variety of threads. It also considers the principles of art that explain the polymers required in the creation of the textile surface.

It focuses on the design and control of the fibre, machinery, and products, and apparel and textile process. Textiles are seen everywhere be it clothes, bed sheets, draperies, carpeting, upholstery fabrics, or towels. The science behind the production of all these things is Textile Engineering. Textile engineers design and develop the processes, equipment, and procedures that create all these fibres, fabrics, and Yarns. Therefore, let us look at some of the career opportunities in Textile engineering which one can go for after class 12th.

Medical Textile Engineer after Textile Engineering

An important field of application of textile in medicine has been developed such as wound care and preventing chronic wounds. Bandages and wound dressings are most commonly used because they are affordable and reusable. Medical textiles should have bio-compatibility, flexibility, and strength. Textile Engineers are involved in textile harvesting, which includes production, processing (applying engineering principles and theories). They work with fibres, fabrics, and other textile materials in order to improve current textile products and bring out new ones. In a marketing and sales role, he is responsible for coming up with marketing strategies to ensure the sale of products. A textile engineer should play an important vital role in a textile mill for continuous smooth running and further development of the mill. Therefore, you can go for this role after class 12th under the textile engineering field.

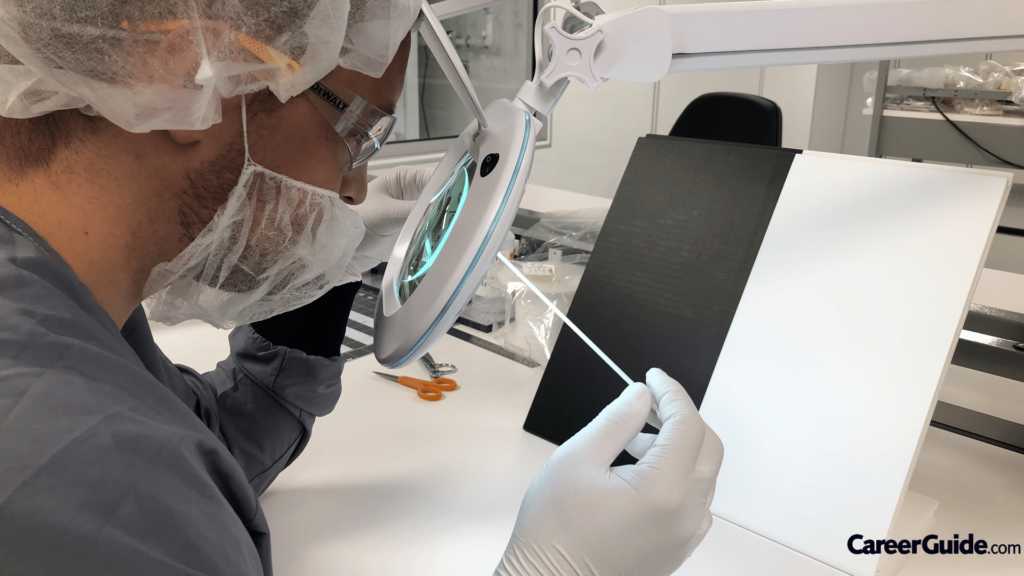

A Medical Textile Engineer is a professional who specializes in the design and development of textiles and materials for medical applications. They use their knowledge of textile science, engineering, and medical principles to create products such as surgical gowns, bandages, and implants.

After completing a degree in Textile Engineering, an individual can choose to specialize in medical textiles by pursuing further education and training in the field. This may include a graduate program in biomedical engineering or a specialized program in medical textiles.

Medical Textile Engineers are responsible for designing and developing textiles that meet the specific needs of the medical field. This includes creating materials that are sterile, biocompatible, and able to withstand the demands of different medical procedures. They must also consider factors such as durability, comfort, and cost when designing their products.

In addition to designing and developing new products, Medical Textile Engineers may also be responsible for testing and evaluating existing products to ensure they meet the necessary standards and regulations. They may also work with medical professionals to identify areas where new or improved products are needed.

Process Engineer after Textile Engineering

Process Engineers, also known as Chemical Engineers, develop scientific processes for converting raw materials into products. They often work in the pharmaceutical or food and beverage industries and are responsible for developing, testing, and implementing new production processes. They are responsible for the task of overseeing and assessing existing processes and workflows. They optimize productivity by designing, implementing, and testing new procedures, assembles reports to document process status and changes, tracks metrics to discover areas for improvement and monitor upgrades, communicates findings and proposals to upper management, utilizes process simulation software to test and find the most appropriate production strategies, provides thorough instructions for successful implementation of process changes, conducts risk assessments, assesses compliance with applicable safety and quality standards, contributes to departmental efforts by accomplishing related tasks as needed. Thus, if you think that you can implement the production processes comfortably, then this field is for you after class 12th.

A Process Engineer is a professional who specializes in the design, development, and optimization of manufacturing processes. They use their knowledge of engineering principles and techniques to improve the efficiency, quality, and cost-effectiveness of manufacturing operations.

After completing a degree in Textile Engineering, an individual can choose to specialize in process engineering by pursuing further education and training in the field. This may include a graduate program in manufacturing engineering or a specialized program in process engineering.

Process Engineers are responsible for designing and developing manufacturing processes for textile products, such as yarns, fabrics, and clothing. They must consider factors such as material properties, equipment capabilities, and production volume when designing their processes. They also work to optimize existing processes to improve efficiency, reduce costs, and enhance product quality.

Operations Trainee after Textile Engineering

An operation trainee is responsible for the task of completing all assigned tasks and assisting with day-to-day operations. They are responsible for the task of participating in meetings, workshops, and other learning opportunities. The responsibilities include the task of observing and learning from experienced staff members, gaining knowledge of company policies, protocols, and processes. They work under the supervision of managers and executives in organizations. Their goal is to acquire all essential knowledge to become future managers, often in particular fields, such as marketing, sales, or operations. They contribute to strategic planning and help evaluate employee and department performance. They also have various responsibilities and requirements based on the industry. Therefore, you can be sought after this field as well.

An Operations Trainee is a entry-level professional who is learning about the day-to-day operations of a company and working to develop the skills and knowledge needed to advance in a career in operations management. They may work in a variety of industries, including textile manufacturing.

After completing a degree in Textile Engineering, an individual can choose to start their career as an Operations Trainee. This role may involve working in a textile manufacturing company and learning about the various aspects of the production process, such as production planning, inventory management, and quality control. The trainee may also work with other departments, such as logistics and supply chain, to understand how they interact with production operations.

Operations Trainees are responsible for learning about the various systems and processes used in textile manufacturing, such as textile production, spinning, weaving and finishing. They may also learn about how to improve efficiency and productivity of the textile manufacturing process. They also may be responsible for maintaining accurate production records, monitoring production performance, and identifying areas for improvement.

Quality Control Supervisor

Quality Control Supervisor oversees and monitors the inspection and testing of materials, parts, and products to ensure adherence to established quality standards. The supervisor establishes inspection protocols, defines sampling procedures, and determines equipment and mechanisms to be used in the testing process. They direct audit activities commensurate to production schedules, establish priorities and ensure maximum usage of assigned resources, develop monthly reports showing inspection and audit performance and improvement opportunities, evaluate and recommend alternative auditing procedures for continuous improvement, support production leads and operators for interpretation and methods following set standards, maintain working production component’s knowledge and associate next tier application, conduct meetings regularly with inspection and audit team to help consistency in teamwork and involve in team-driven actions to help improvements.

A Quality Control (QC) Supervisor is a professional who is responsible for overseeing and coordinating the quality control activities of a company. They ensure that products and services meet the required standards of quality and are fit for their intended use. They work in a variety of industries, including textile manufacturing.

After completing a degree in Textile Engineering, an individual can choose to specialize in quality control by pursuing further education and training in the field. This may include a graduate program in quality management or a specialized program in quality control.

The QC Supervisor is responsible for developing and implementing quality control systems, procedures and standards to ensure that products meet the required quality levels. They also conduct and supervise inspections, audits and testing to ensure that products meet the required standards. They also work to identify and correct any quality issues that arise, and work to prevent recurrence of such issues.

Process Improvement Engineer

Industrial engineers find ways to eliminate wastefulness in production processes. They devise efficient systems that integrate workers, machines, materials, information, and energy to make a product or provide a service. They work with management to identify new process improvement opportunities in the areas of quality, cost, performance, and preventive and predictive maintenance. They evaluate and analyze current process metrics and performance to identify areas requiring improvements. Therefore, if you think you have the capability to eliminate the unnecessary material, then textile engineering will be the right path for you after class 12th.

A Process Improvement Engineer is a professional who specializes in identifying and implementing changes to improve the efficiency, quality, and cost-effectiveness of manufacturing processes. They use a variety of tools and methodologies,