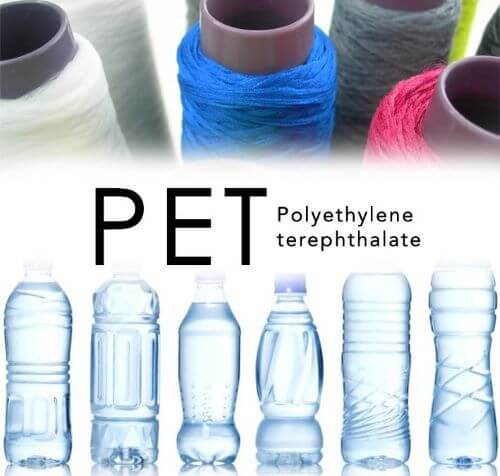

PET stands for Polyethylene Terephthalate. It’s a strong, clear, and shatter-resistant plastic. You often find it in things like water bottles, packaging, fabrics, and car parts. It starts as a flexible, colourless material. But how it’s made can make it firm or a bit bendy. It’s similar to another plastic called Polybutylene Terephthalate.

Table of Content

- PET full form: Key Properties of PET Resin:

- PET full form: Chemical Properties:

- PET full form: Major Uses of PET products:

- PET Full Form: How is PET made?

- PET Full Form: Properties of Polyethylene Terephthalate

- PET Full Form: Characteristics of Polyethylene Terephthalate

- PET Full Form: FAQ’s about PET

Key Properties of PET Resin:

- Its strength and stiffness are higher than PBT.

- It is lightweight and strong so can be transported easily without any damage.

- It has gas and moisture barrier properties.

- It is a good electrical insulator.

- It can be used over a wide range of temperatures, from minus 60 to 130 degrees centigrade.

- It has a higher heat distortion temperature (HDT) than PBT.

- It is a better alternative for glass in some applications as it is shatter-resistant.

- It is approved by the FDA as a safe material for contact with food items and beverages.

Chemical Properties:

It is resistant to alcohols, oils, greases, and diluted acids. However, it is less resistant to aromatic hydrocarbons, and diluted alkalis.

Besides so many advantages, there are also some limitations of Polyethylene Terephthalate:

- The impact strength is less than PBT.

- Its crystallization rate is slow than PBT, so its moldability is less than PBT.

- It is affected by boiling water.

- It is sensitive to strong bases and alkalis.

- It has poor burning behaviour.

PET can be blended with other thermoplastics and thermosets to improve its performance and to use it for different purposes. The purpose of producing its blends is to improve cost-effectiveness and its properties such as mechanical strength, flame retardancy, processability, etc.

Major Uses of PET products:

- For manufacturing water bottles and carbonated soft drinks bottles like coca cola, Pepsi bottles, etc.

- To create packaging trays

- To produce PET film to use in tape application

- To make the cosmetic jars, microwave containers, and other such packaging items

- To make mesh fabrics required in printing, filter oil, filter cloth, woven belt, etc.

- To make wiper arm, gear housing, engine cover, etc.

- To make polyester fabrics that are flexible, firm and resistant to shrinkage as compared to cotton

- Besides this, the recycled PET can be used for various other purposes such as to make carpets, tote bag, comforter fill, film sheet, strapping, etc.

How is PET made?

PET is created through a process where tiny building blocks, called monomers, are formed. These monomers come from mixing terephthalic acid and ethylene glycol or dimethyl terephthalate and ethylene glycol. When these monomers react, they link together like a chain in a process called polycondensation. This creates PET.

This PET comes out as a hot liquid that can be shaped. You can spin it into thin fibers, like the threads in clothes, or shape it into all kinds of things. This makes PET very versatile. It’s used to create clear plastic bottles for drinks, strong fabrics for clothes, and even parts in cars. The way PET is made affects its flexibility – sometimes it’s flexible like a bendy straw, and other times it’s sturdy like a water bottle.

So, PET starts from simple pieces, gets linked together, and then can be turned into all sorts of useful things.

Properties of Polyethylene Terephthalate

- Strength: PET is a strong material that is resistant to tearing and breaking. It has a high tensile strength, which means it can withstand a lot of tension before breaking.

- Lightweight: PET is a lightweight material, making it easy to handle and transport.

- Durability: PET is a durable material that is resistant to wear and tear. It can withstand high temperatures and is resistant to UV radiation, making it suitable for outdoor use.

- Chemical resistance: PET is resistant to many chemicals, including acids, bases, and organic solvents.

- Transparency: PET is a transparent material, making it suitable for use in applications where clarity is important, such as in packaging materials.

- Dimensional stability: PET has good dimensional stability, meaning it retains its shape and size under a range of temperatures and humidity conditions.

- Recyclability: PET is a recyclable material, and it can be melted down and molded into new products.

Characteristics of Polyethylene Terephthalate

- Molecular Structure: PET is a polyester polymer formed from ethylene glycol and terephthalic acid monomers. It has a repeating chain of units, each consisting of two ester bonds.

- Thermal Properties: PET boasts a high melting point and excellent thermal resistance. It can endure high temperatures without melting, making it ideal for high-heat settings.

- Electrical Properties: As a strong insulator, PET exhibits high dielectric strength and low electrical conductivity. It’s resistant to electric charges and doesn’t attract static electricity.

- Optical Properties: PET’s transparency shines with high light transmission and minimal light absorption. Its optical clarity remains steady, avoiding yellowing as time passes.

- Chemical Properties: PET defies various chemicals, including acids, bases, and organic solvents. It’s also unfazed by UV radiation and resists degradation or corrosion.

- Mechanical Properties: With solid tensile strength, PET resists tearing and breakage. It’s pliable and easily molded, adapting to different shapes and needs.

- Recyclability: PET’s recyclable nature allows it to be melted and formed into fresh products. It’s also environmentally friendly, biodegrading naturally and not lingering in the environment.

FAQs About PET

ITC Limited is an Indian multinational conglomerate with diverse business interests including FMCG (Fast-Moving Consumer Goods), hotels, agri-business, paperboards, packaging, and more.

ITC’s name originally stood for “Imperial Tobacco Company of India Limited.” It has evolved over time to reflect its diversified business focus.

ITC operates in various sectors, including FMCG, hotels, agri-business, paperboards, and packaging. These divisions contribute to its diverse revenue streams.

ITC has strategically diversified its operations over the years, expanding into non-tobacco sectors to reduce dependence on a single industry.

ITC engages in various Corporate Social Responsibility (CSR) initiatives, including education, healthcare, rural development, and women’s empowerment, to uplift communities and promote social progress.